Application of RFID Technology in Chicken Breeding Traceability: Technology Enhances Food Safety and Transparency

Advancements in technology combined with heightened consumer awareness regarding food safety have led to growing adoption of RFID (Radio Frequency Identification) for poultry breeding traceability. By tagging chickens, this technology automates data collection and management during the breeding process, enhancing scientificity and transparency, thereby elevating food safety and traceability standards.

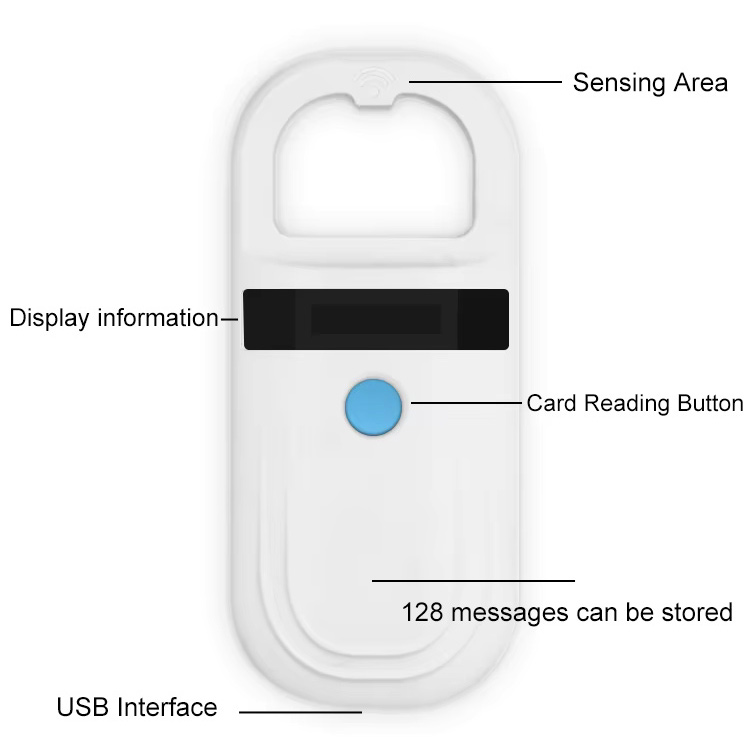

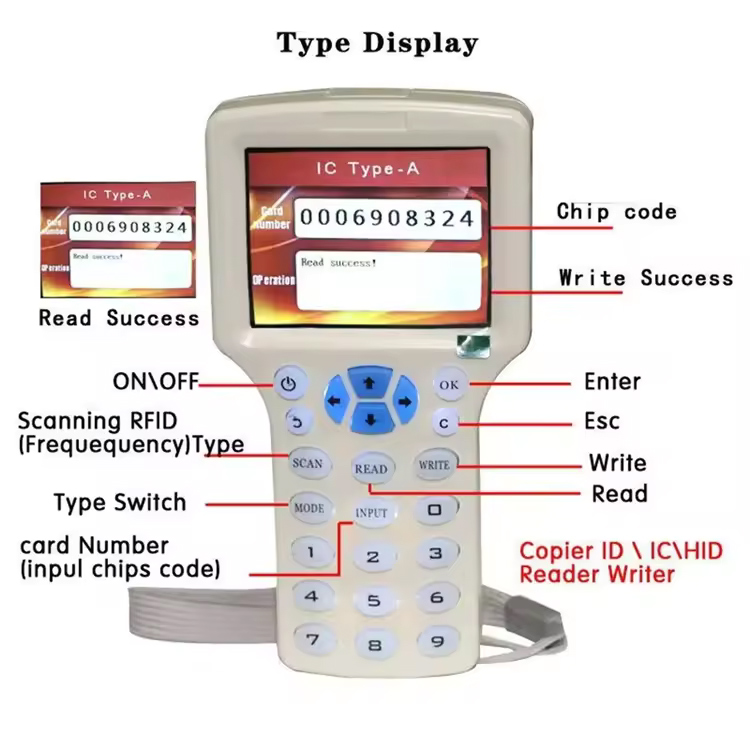

The application of RFID in poultry breeding traceability encompasses bird identification and tracking, environmental monitoring, and production management. By implanting an RFID chip into each chicken and installing readers for information collection, individual birds can be tracked, located, and monitored within a farm. This also enables creation of unified information profiles for each chicken, including breed, birth date, gender, vaccine status, etc., enabling real-time understanding of their health and growth by managers.

System Function Composition

RFID technology aids managers in establishing a poultry breeding production management platform through establishment of a comprehensive production file for chickens. It ensures comprehensive management and control of chicken growth stages from birth to sale, ensuring safe and stable poultry breeding production.

I. Data Statistics: The system automatically tallies the total number of animals, messages received, sales revenue, and total orders.

II. Data Analysis: The system conducts weekly, monthly, and annual data analysis, generating corresponding charts that visually display data trends.

III. Batch Management: Animal batches are managed, recording supplier, logistics, and time information. The system classifies tracing back to a specific batch at this stage.

IV. Animal Marking: Animals are marked at certain stages for record keeping. For example, in chicken farming, unique code RFID anklets are worn by chicks, which contain an RFID chip and a corresponding QR code for later traceability.

V. Slaughter: Slaughter is also classified according to batch. Slaughterhouses register detailed information per batch, read the RFID chip on the anklet using fixed equipment, and bind the slaughterhouse and slaughter personnel's information to the chip for future traceability.

VI. Traceability: When the chick wears the anklet, the actual traceability begins. Information such as chicken growth environment, breeder, feed, vaccines, etc. is recorded in the RFID anklet. Slaughter records information about the slaughter environment, slaughter personnel, etc. in the RFID anklet, and subsequent cold chain links also maintain relevant records. The previous traceability information can be viewed via scanning the QR code on the anklet surface.